3D Resin Printing

At the end of last year my employer finished negotiating with the unions on the annual pay increase and a bit of extra money found its way into account. Hooray, and just before Christmas as well! Did I spend it on the nearest and dearest? Well clearly dear reader I didn't, as Elegoo had an offer on their Mars 5 Ultra resin printers.

We've got a filament 3D printer at work, and I realised after attempting a test model (or two) of tabletop fantasy figures the resolution just wasn't good enough. With that research in mind 3D printing using photoreactive resin seemed to be the answer for my D&D needs. Of course, what I should have done was to have watched this excellent video before I hit "purchase now". I didn't and then found myself in a world of managing toxic liquid, fumes, and disposing of waste safely.

And I'm glad I didn't as it would have put me off. Instead, I'm now "successfully" printing out objects and learning how to prep, slice, print, clean, cure and more importantly have rekindled a desire to paint miniatures.

3D printing takes a long time, and Elegoo provide a time-lapse video (depending on size of model) of the build process. Watch as things emerge for toxic soup.

Dice tower base rises from the resin

Dice tower side rising from the resin

The dice tower below is almost finished but needs mini dried vines twisting around the tower as well as cork rocks and skulls in the courtyard.

The STL files for the 3D Warhammer Fortress of Sacrifice Dice Tower is below, but for the Mars 5 Ultra I had to reduce to 75% of the original size as the largest parts wouldn't fit on the build plate.

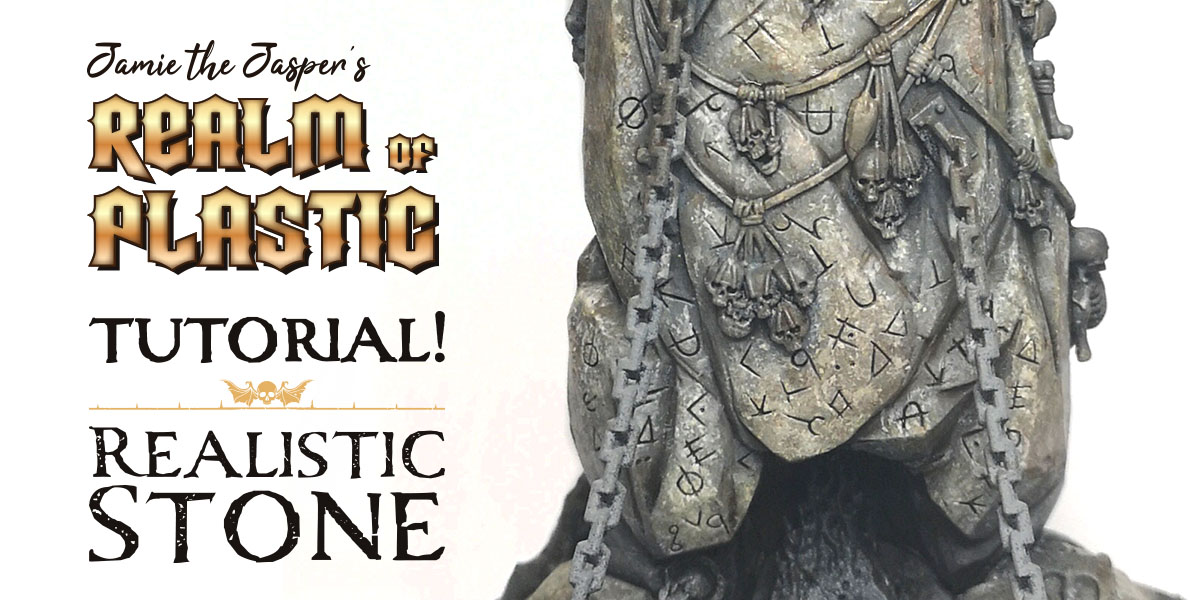

After printing, cleaning, curing, spraying on a Citadel black base coat, and assembling I headed over to the Realm of Plastic and followed this paint tutorial.

The current paint project is this Dead Space Necromorph bust, it's early days for this figure with base, bruising, blood, mouth, tongue, and teeth still to do.

So far here are all the mistakes that I as a newbie printer have made:

- Resin too cold.

- Not filtering resin after use.

- Spilling resin.

- Not enough build supports.

- Initial layer exposure set for too long and welding the model to the build plate.

Thankfully though the printing gods smiled on me when I spilt resin into the cavity of the printer. Quickly realising the clumsy mistake, I powered off the printer and tipped it onto its side so that the resin would run away from the lens. It took a while to disassemble the sides so that I could clean with isopropyl alcohol but as I type the printer is well, printing...